Would you like to...

Eat better, fresher and save at least 5%)?

Choose from thousands of recipes in a web library,

No more cooking and cleaning pots.

See how three parties win (win -win -win!- you, the environment and the seller) and

The packaging waste, colorful brochures, queues disappear,

(who does not believe, should read on!) You experience the revolution of food trade for the time being in www.freshfood-zero-waste.de

You, just back home, are part of the FCS, the new Food Chain System. Instead of the "old" kitchen, you have the “Tireless Cook", a piece of technical furniture with lots of amenities. First of all, you can get all the information from the Front Panel Display. Next to it, you can stick your hands for a few seconds in the "Clean Storm" which, without wasting paper, does its job, while the "Drinks Boy" serves you, for example, tea, hot or cold coffee, and more. Afterwards, "T.Cook" lets you know that the dish you ordered is ready. Enjoy! Please read on to find out more.

Food trade without throwaway packaging.

Something completely new, the future of food trade! a step towards automation that gives people more free time.

The motivation for this idea is the problem of discarded packaging.

The food from (agricultural field, a factory, a butcher's shop, ... etc.) comes to the trade mostly packaged in different ways, in a way that is difficult to recycle.

On the one hand, this packaging costs money (more than 5% of the value of the goods) and, on the other hand, its use involves a waste of time and materials, both in its use and in its so-called "disposal".

However, the buyer does not get what he/she wants or needs, but what is available.

The packaging (in its type and its size) corresponds to the criteria of the manufacturer or the dealer, not to those of the customer.

The goods packed in this way lie for some time on the shelf or in the presentation tray at the food retailer or in the supermarket and are bought at some time, no longer quite fresh, by the consumer.

From this moment on, the handling (bumping, falling off) and hygiene is in the hands of the buyer. If the goods are well packaged, this is usually easy to handle.

But after emptying from the packaging, this packaging becomes waste, an as yet open problem.

Because the "disposed of" packaging appears again. For example in Poland, Thailand or in the Sargasso Sea.

The best solution is to get rid of it from the outset, or more precisely: not to use it in the first place.

This is possible if the transport from the producer to the consumer's Plate is fundamentally improved. Now we come to what's new.

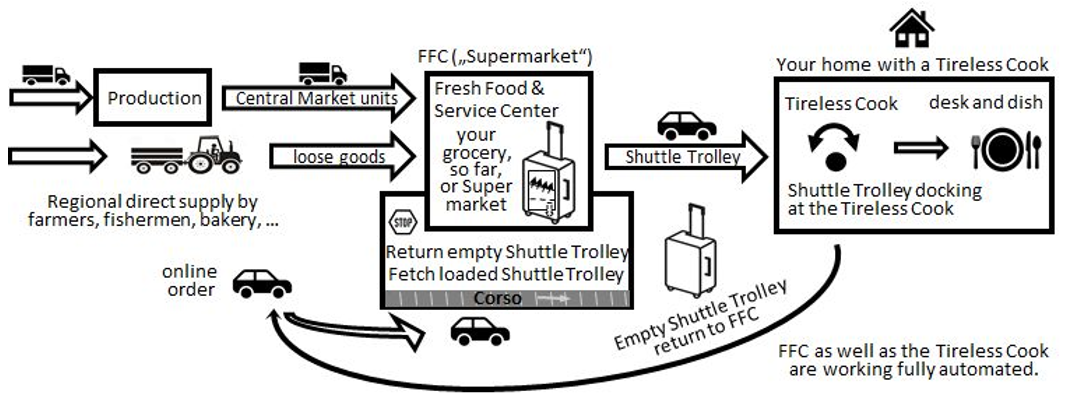

We have developed the Food Chain System (FCS), which meets transfer requirements without producing waste. This is something that is really new.The FCS system assumes that at the retailer, i.e. at the food vendor, by means of a portioning machine, your specified transfer container (shuttle trolley) is filled according to the recipe order.

Also at the customer's the goods arriving there in this container to the "tireless cook", will arrive in the same order.

The highly productive automatic portioning machine, which serves thousands of customers, does not produce an "ingredient salad", but spits out, with the help of its "sorting brother", for each customer sets of ingredients corresponding to the recipes that the customer has ordered.

The shuttle trolley makes sure that these sets of ingredients arrive well protected to the thousands of small "sons" of the "big" portioner (the "tireless cooks") and there, without any sorting in the given order, are handed out to finished dishes according to the recipe. The customer gets what he ordered as quickly as possible and no hand has touched the fresh ingredients.

The split- solution of centralized portioning machines and the peripheral "tireless cooks" allows these last to have a simple, affordable structure. This is due to the fact that the ingredient sets, sorted with the help of the shuttle trolley, arrive orderly where they need to be processed. The "tireless cooks" are only executors of simple placement operations to fixed points, with predetermined time intervals, depending on the recipe. The central computer connected to all these units ensures that no deviations occur. That is the fundamental feature of the new system. It sounds unspectacular at first, but it has a tremendous number of advantages for everyone involved - and far-reaching consequences.

For the time being: The double automation eliminates the need for packaging material.

Sales will be significantly speeded up.

A win-win-win situation is created for the environment, for consumers and for sellers.

I would like to point out an anachronism here, according to which a person always has to supervise the preparation of food in the kitchen, which more or less succeeds.

Today we live in an age of automation, where a "Tireless Cook" can cook to technical perfection, keeping precise time and temperatures for food processing, and not getting distracted because the baby is crying at the moment. This "Tireless Cook" stays on task, doesn't need to be taught, doesn't need to be supervised, and has mastered the use of thousands of recipes of every flavor. He also does the dishes and cleans himself.

The modern kitchen, which is not exactly inexpensive, has a large number of appliances, but each of them only performs individual steps; the cook has to switch them on, adjust them, monitor them and (usually also) switch them off.

A "Tireless Cook" controlled by a digital recipe can perform these operations perfectly and need not cost more than the appliances that nowadays pile up in the kitchen and are then no longer needed.

The "Tireless Cook" chains the phases of culinary operations and gives people more free time. Now in detail: the new process

FCS does not sell food somehow packaged, but exactly the ingredient sets required and ordered by the choice of the desired recipes.

This begins with the selection and the decision of the customer for one (or more) recipes from the extensive collection of tried and tested dishes, to be found on the smartphone, also to be ordered there.

All audiovisual and in the own language and writing. Finally, a recipe number is given and, in case of deviation, the desired (special) quantity. Within a few seconds, you'll receive feedback that you can pick up the order right now, either yourself or through a delivery service.

In addition to the price information, there is further additional information about each recipe, such as flavor, calorie content, duration of preparation, and, if required, whether it is vegetarian, vegan, gentle on the stomach, whether it is suitable for diabetics or as part of a special diet, and so on.

Further (or less) explanations are given to the customer upon request.

Customers can subscribe to deliveries for desired times. They also create their own recipes, which are then stored in their personal file.

Digitization also eliminates paper waste here.

Once the trolley is there, it is set in the parking position on the cooking machine and the time for the meal is entered, e.g. "as soon as possible". That is all. The "tireless cook" reports when the meal is ready.

Sales

The FCS sales unit is called "Fresh Food & Service Center" (FFC). It processes customer orders by means of the wholesale assortment that it has in stock or in refrigeration. Upon delivery, these fresh goods are registered, automatically stored and ready for sale. At any moment the available quantity is known.

When an order is received, there is an immediate response that it is available and can be picked up (by shuttle trolley). The products are then automatically driven to the portioning station, weighed, divided, and the unused remaining quantity is put back into storage. The ordered portions are automatically placed into the shuttle trolley in a given order as specified in the recipe.

The shuttle trolley waits within the FFC the arrival (on foot, by bike, by car) of the customer and will be imediatly be commisioned at the transfer point where the customer stops, is identified and takes it.

A note: Hello Fresh's system works similarly, only slower, more expensive and with a smaller assortment, all packed in "boxes" that become waste. In addition, the cooking must be done "by hand" at home.

At the Corso, the "shuttle trolley" from the previous purchase (with the leftovers) can also be returned.

Leftovers are recycled for pet food, etc.

FCS, through the sale or lease of the "tireless cook," provides the buyer with the options described above. This can only work because the FFC (retailer) owns the portioner (plus automated warehouse), the first automat in the chain of FFC units.

The portioner caters to all customers, or orders on call, day and night, with the high speed of a fully automated machine. It cuts off the quantity required for each order from all the food supplied and places it in each case in a reusable transfer bowl, which is inserted in a specific place in the "shuttle trolley".

The trolley shuttles back and forth between the FFC, where it is loaded, and the shopper's home. It establishes a connection between here and there, it cancels out the distance between the grocery store and the kitchen at home, so to speak.

It creates a fast, hygienic transfer circuit, designed to make the use of the "tireless cook" financially affordable for the consumer.

This automatic cooking machine can be kept simple both mechanically and electrically by taking profit of the handling order imposed by the portioner unit. Using the shuttle trolley, It handles the food "blindly" in a simple and safe way.

It is in the nature of humans to need to eat every day, it is a kind of "automatic need".

Cooking, a handicraft activity that sometimes or for some becomes a chore, can be solved with an automate performance that makes the citizen more productive and satisfied with his life.

In this way, it is possible to discover dishes that you would never have dared to cook yourself.

For those who like fast food: here is the healthy version, just as fast, only more versatile.

See “Memorandum” the advantages and disadvantages for customers, for the trade, for the society

( Patent registered in Germany, 2023 February 21) Reg. Trade Mark, Food Chain System. >> FCS >>>

++++FCS ++++ (Memorandum, 1500 words)

Advantages of the Food Chain System for the food trade

- The goods are delivered and stored in large units.

- The goods do not have to be displayed in the sales floor, there is no need to put away / present items as stuff.

- The presentation is audio-visual with all details by means of an APP.

- No salesroom space is required.

- No salesroom needs to be heated/cooled/illuminated/cleaned.

- Fewer working hours are required (stocking and other work).

- Cashier employees are no longer required, cleaning staff/labor hours are reduced.

- The number of employees can be reduced.

- No parking lot is needed, if necessary the existing one can be reduced.

- There are no plastic bags, no paper advertising, no shopping lists, no checkout slips.

- Portioning and weighing of the required small quantities is automated.

- The feeding of the goods from the warehouse to the portioning and weighing module is automated.

- The customer does not have to follow the package sizes, they follow him.

- Accurate, individual portioning / delivery / provision of the goods.

- No need to collect and dispose of packaging waste.

- Packaging costs are largely eliminated or greatly reduced (by about 5-10% of the value of the goods).

- The justification to plastic waste in (e.g.) Thailand (with German company logo) is unnecessary.

- The company can advertise to save packaging.

- If necessary, a sole agency claim for this system can be used, maybe only in the beginning.

- A new, another sales channel is established, for a new customer base.

- Probably safe customers: Juppies, singles and young families.

- Higher loyalty of the customer to "his" service center, the contact does not end with the purchase.

- With little effort, it is optionally possible to store local deliveries directly in the store's assortment.

- Local goods can be accepted flexibly and efficiently and sold as a special service.

- Special goods (fresh fish) can be offered specifically to some customers (schools, small hotels).

- Such direct offers result in a faster turnover of fresh goods.

Disadvantages of the Food Chain System for the food trade

- It is a new system that only works as a whole system. This must be established.

- Customers have to think differently and change their habits. This makes the introduction more difficult.

- The length of the start-up period and the speed of ramp-up are unknown.

- The trolleys eventually start to wear out, depending on how the customer handles them.

- The introduction of the new system must initially be strongly supported by advertising measures.

- Retailers need to take care of the small, pre-sorted quantities of returns (food scraps, identified, recognized

packaging (no third-party packaging), contaminated cleaning water) to the recycling system.

Advantages of the Food Chain System for the customer *3)

- No more searching for goods on the shelves (time saving 30 minutes)

- The queue at the checkout / unloading and loading of the shopping cart is eliminated (20 minutes)

- There is no need to park and unpark when picking up, loading and unloading is drastically shortened. (20 min.)

- The customer receives his food just as quickly as if he were picking up a pizza.

- He can try new flavors every day, including flavors he would otherwise never try.

- He does not have to know how to cook and does not have to cook (time saving 30-60 minutes)

- He does not have to wash the plates, this is done by the "tireless cook".

- The cleaning of the pots is omitted, or is taken over by the "tireless cook" (time saving 15 min.)

- Overall, the customer saves a noticeable amount of housekeeping.

- The meal takes place on time, fresh and ready prepared, at home.

- Any desired information, digitally recorded, is audiovisually available by clicking on it,

communication is bilateral and individualized, if necessary.

- The information is in the language and writing of the customer (chinese, hebrew, thai, ...).

- There are no plastic bags, no paper advertising, no shopping lists and no sales slips.

- The customer can save the purchase of many kitchen appliances (some of which are low usage).

- The customer can save the related storage space for such kitchen appliances.

- Every action and item (such as a cooking spoon, a stove or a kitchen unit) thus eliminated is an economic benefit, saving time and money, as well as benefiting the environment.

- The kitchen can be made smaller. This is in line with the trend towards smaller houses.

- The customer no longer has to think about what to serve on the table every day, he/she chooses from the existing offers. *3)

- The selection can be made at short notice, no longer has to be planned, including purchasing, for days in advance. He (often she) also no longer has to constantly think up something new.

- The task of coordinating child care vs. shopping becomes easier.

- The need to coordinate taking care of the children vs. cooking and doing the dishes is omitted.

- Shopping is done without worrying about contagion in times of a possible further pandemic.

- Individualized food is suggested in a health-oriented way. Risks can be emphasized.

- Optionally, food can be selected according to the customer's health condition.

- Optional: warnings if recipes are chosen that are harmful to the customer's health.

- This option simplifies the diet in the presence of diabetes, obesity, allergies ... .

- Through health warnings, affected people are warned of (possibly life-) hazardous malnutrition.

- Pensioners, sick people, disabled people receive an individually tailored, healthy diet.

- Special requirements (allergies, low-fat, gluten-free, stomach-friendly, low-caloric, ...) are reliably taken into account without being forgotten and without triggering extra effort.

Disadvantages of the Food Chain System for the customer

- Customers have to rethink and change habits.

- The FCS is not intended for food storage, but it can work on a contract basis.

- As long as a delivery system is not used/created, the customer will have to pick up the shuttle trolley, just as they go shopping every two or three days today. One has to get used to the extended frequency, at least as long as there is no adequate delivery service.

- For individual, health-oriented advice, the customer must release some sensitive data.

- The customer must buy a "tireless cook." (This can be produced affordably).

Advantages of the Food Chain System (FCS) in general

- The reusable bins of the shuttle trolley can be used hundreds of times in an automated way.

- The generation of packaging waste is almost zero, so is the input into the evironment.

- The waste disposal balance of the area improves, triggered by the FCS system use.

- The stress reduction facilitated for moms is a valuable socioeconomic component.

- Users are reminded to eat mindfully through notices. This cuts down on medical costs.

- The FCS integrates data storage, electronical billing, caloric indication, portion pricing, nutritional advice, suggested eating, ... . A useful statistical information.

- High hygiene standards, no hand touches the food.

- There is less noise, there are additional clean-up aids, keeping order is simplified.

- Most cleaning procedures are then automatized.

- The processing of individually coordinated food sales with the help of data networking with digitized medicine makes it possible to make nutrition more healthy.

- Important in pandemic times: Crowding is avoided.

Disadvantages of the food chain system in general: Not known so far.

*3) This description uses the generic masculine: "the customer" is w/m/d.

FCS from the consumer's point of view

For the customer (here, in this description, assuming it is a man), the process starts with,

That he wants to eat something, or that he plans a meal.

He picks up his phone, opens the FCS app, and looks to see which dish from the menu is available to him today.

(or for the planned meal).

For this, he opens his favorites in the quick access, or he enters the desired ingredients,

e.g. turkey, cauliflower, rice, lamb's lettuce.

From the offer that appears, he selects e.g. No. 571 and orders 1 portion.

He could change the portion size, if necessary.

Within less than 1 minute he receives the confirmation that the order can be picked up.

If the customer is still at work, he turns off on the way home to the customer corso of his Fresh Food & Service Center, the (now) automated version of the grocery store.

He stops at a free pickup point.

There, he picks up the trolley with the contents and, if necessary, returns another trolley, just as deposit bottles are returned today, only without a cash register and without waiting in line, i.e. now within seconds. The return is booked to his account.

When he arrives home, he places the shuttle trolley in the docking station of the "tireless cook".

He still decides when the dish should be ready, at a desired time, "as soon as possible" or

"after 20 minutes", "after 2 hours", as desired.

With this, he has done what he needs to do. He can devote himself to his after-work time.

For more details please contact: cornelius@freshfood-zero-waste.de

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.